Supports decisions to synchronize your production and supply chain.

The essence of TOC for operations is to focus on the correct Throughput Constraints.

C&DS provides decision insights for all operational functions.

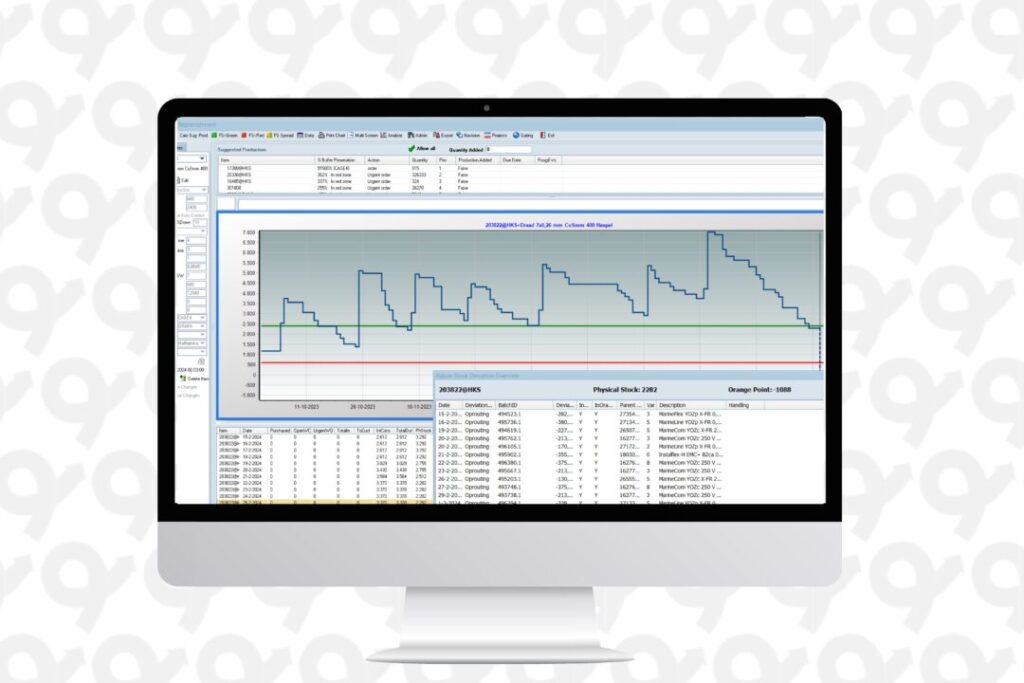

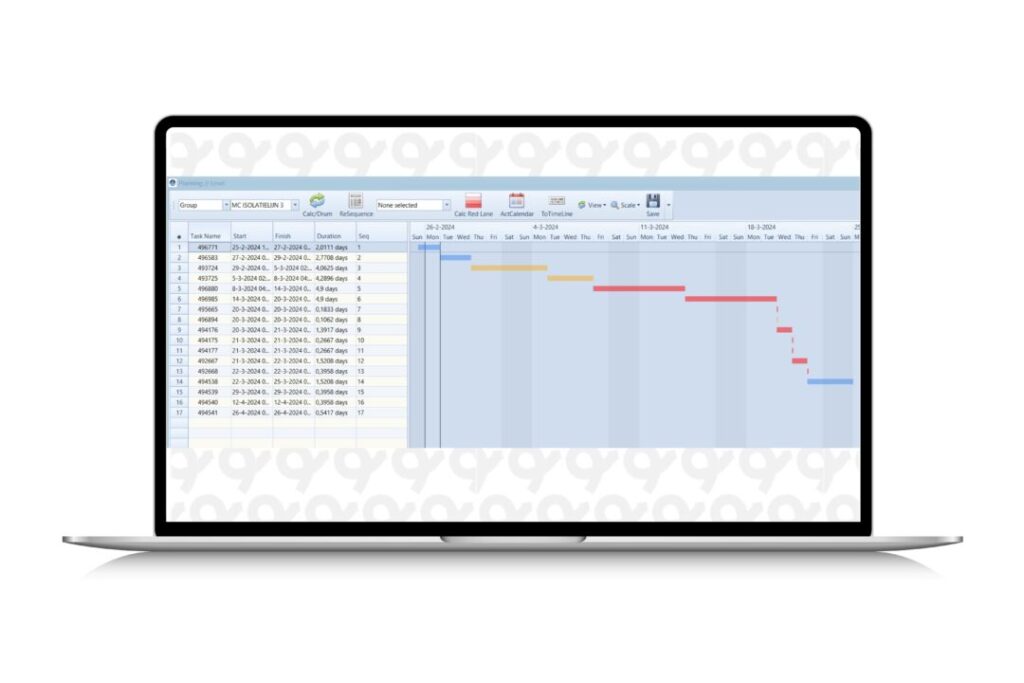

Finite Capacity Planning

A necessary tool for making operational decisions. Each customer request can be reviewed before making a commitment, taking into account operational constraints (Capacity, Inventory).

Focus on the bottleneck and buffers guarantees a stable planning in line with reality without becoming over sophisticated.

MTO (Make to Order) MTS (Make to Stock) Or MTO MTS combination.

Availability at minimum Inventory

Purchasing / Finished goods / Raw material / Semi finished goods / Supply chain.

C&DS Classic algorithms or DDMRP Logic.

These technique have dynamic adjustments, pipeline control, continuous monitoring for (often rapidly changing) priorities. Supports the right Make/Buy/Ship/Priority decisions to guarantee availability at minimum inventory on all levels of the supply chain.

Availability at minimum Inventory

Purchasing / Finished goods / Raw material / Semi finished goods / Supply chain.

C&DS Classic algorithms or DDMRP Logic.

These technique have dynamic adjustments, pipeline control, continuous monitoring for (often rapidly changing) priorities. Supports the right Make/Buy/Ship/Priority decisions to guarantee availability at minimum inventory on all levels of the supply chain.

Performance Measurements

A strong and reliable delivery performance with minimal inventory is one of the outcomes of operations guided by C&DS. Performance measurements are coherent and built into the logic. Every decision-maker can have an online view of the real performance and reasons for deviation.

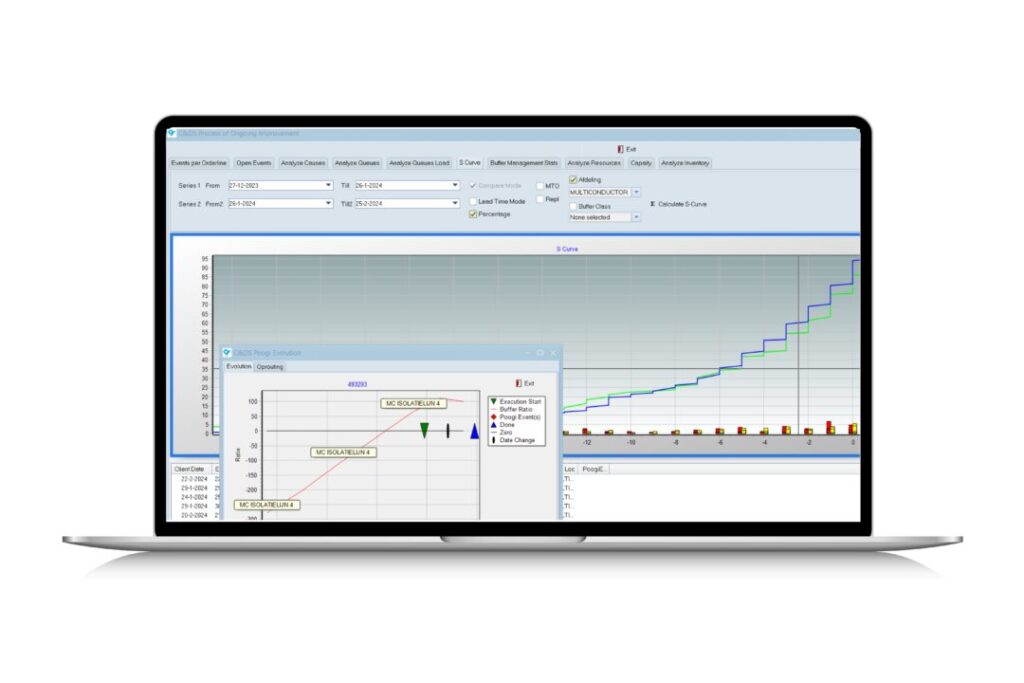

Buffer management for execution

Is a unique technique that creates the necessary protection for a global supply chain and avoids over-protection. The correct signals are crucial for achieving a smooth flow, and therefore, the built-in monitoring system is necessary to ensure delivery performance. The same mechanism is used to guide priorities in execution to create a coherent environment.

Buffer management for execution

Is a unique technique that creates the necessary protection for a global supply chain and avoids over-protection. The correct signals are crucial for achieving a smooth flow, and therefore, the built-in monitoring system is necessary to ensure delivery performance. The same mechanism is used to guide priorities in execution to create a coherent environment.

POOGI

The TOC Process Of On-Going Improvement is a diagnostic tool for mapping the obstacles to flow by using a combination of Queue monitoring and event tracking . It is also the platform for online communication for operations . It includes reporting on causes and automatically generates Pareto analyses to identify the most impactful causes . It avoids wasting time on symptom and provides the right signals for identifying the next constraints.

Curious about what C&DS can do for your company?

For contact please write an email to: patrick@leonard.be.

Read more

TOC as a Path to Antifragility

TOC as a Path to Antifragility In recent years, uncertainty, complexity, and variability have become everyday aspects of our reality. Traditional methods of risk management have proven to be ineffective. It is futile to create a semblance of precision in an uncertain environment through detailed planning or to break down an organization into smaller parts…Read More

More

TOC Disaster

I like to share a screenshot from a leaflet from the 1990.It is from a publicity for Eli Goldratt’s planning software “Disaster.”The name “Disaster” was a provocative warning. “It is impossible to change a company’s culture trough a computer.” (This is why Eli wrote the book the goal).Without real understanding of the algorithm and the…Read More

More

An alternative to process mapping

There is a lot to be said for mapping out the processes before tinkering with them, because in that way a lot of incomplete routing, sometimes the one way and sometimes the other, wrongly used processes, and you name it, comes to light. Anyone who has ever experienced an ERP implementation knows many stories about…Read More

More

Scan and Plan Market Constraints

TOC Scan & Plan and Market Constraints The TOC-SCAN & PLAN can be expanded with the market constraints training module and provides answers to the following questions:

More

TOC and the congestion problem

Can the congestion problem be solved with TOC? Traffic jams in Groot Bijgaarde, an accident at 6 o'clock in the morning causes enormous chaos. Driving times from Ghent to Brussels run up to more than 3 hours, everyone knows the problem. Moreover, there is now no budget to redesign the entire road infrastructure and build…Read More

More

Business stability has disappeared – What now?

This post opens up original ways of thinking for those looking for a new way to steer their business in the current unstable economic climate. With the topic of business (un)stability, we want to create an insight into an alternative way to steer both the manufacturing industry and trade and services according to techniques that…Read More

More

Intelligent lean

Intelligent lean: A strong component of your business strategy for 2021-25. In contrast to the classic lean approach, intelligent lean is like an outsider but with a much broader scope of application. It is a derivation of the TOC technology for flow control, which, by definition, does not begin to move workstations or machines. This…Read More

More

A new scarcity: management time

It is a general adage: Managers walk from one meeting to another and no longer make time for longer-term thinking. In addition, pressure is sometimes seen as a status symbol! This leads to the inevitable vicious circle that you no longer have time to make time. What has changed? The organisations have been slimmed down…Read More

More

Proven recipes for failure

Proven recipes for failure: Experience In management conversations, the beautiful word "experience" is sometimes used to softly disguise past failures. However, some of these "experiences" lead to failures so systematically and predictably that it is certainly worth reflecting on them. Part 1: "When everyone sweeps in front of their own door..." Yes, ... then the…Read More

More

How do companies react in times of crisis?

So what difference does it make between the survivors, the winners and the others? A first category Conservatives try to deny the phenomenon and continue 'business as usual'. Turnover is falling, but no one is to blame for that, it is crisis for everyone, isn't it? With this reassuring thought, no one feels the need…Read More

More

CHANGE MANAGEMENT with TOC-TP techniques.

Several examples of change management already in use.

More

Resistance to change

Resistance to change does not exist and that can be proven in a very simple way. Suppose you receive €10,000,000 from us as a gift without conditions. For most of us this is a very profound change in our lives, there is usually no resistance. Resistance to a change only exists if the consequence of…Read More

More

C&DS applied: supplying construction sites

Centrally controlled supply of construction sites. It is a well-known phenomenon that construction sites with more complex installations and supplies are often delayed due to the lack of one or other albeit small part. An average shipyard has no or very limited administrative support and the yard manager usually has something else to do than…Read More

More

The evolution of TOC process synchronization

The past Since the first applications of the DBR – technique in the 80’s some important additional TOC-related techniques and tools have been developed to support the 5 steps-process that are the result of a regular TOC-implementation. Before that stage, TOC could be perceived as another optimization algorithm like linear programming etc… The present and…Read More

More

TOC and APS

The necessary conditions for APS Conclusion Looking at the finite capacity-planning picture one could have the feeling that trying to improve the throughput while having fewer inventories and less operating expenses is a mission impossible. If we try to apply the regular (finite-capacity) solutions the answer is: YES! For getting a realistic solution to this…Read More

More

Joe the Efficient Expert

In discussing the costs incident to various types of operations, the analogy was drawn of the restaurant, which adds a rack of peanuts to the counter, intending to pick up a little additional profit in the usual course of business. However, the accuracy of the analogy is evident when one considers the actual problem faced…Read More

More